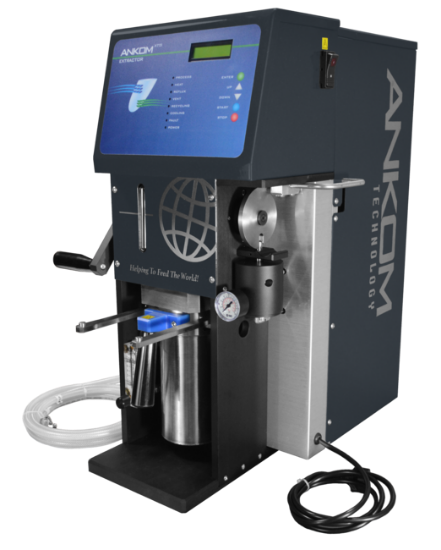

The Ankom XT15 Automated Extractor is a high-throughput solvent extraction system designed for efficient, cost-effective crude fat determination across a wide range of sample types. With a fully automated process, integrated solvent recycling, and batch capabilities, it provides an official AOCS-compliant method that simplifies fat analysis in demanding lab environments.

Product Features

- Official Crude Fat Extraction Method (AOCS Am 5-04) for accurate fat determination from 0% to 100%

- Fully automated operation with microprocessor control and easy-to-read LCD interface

- Processes up to 15 samples simultaneously; handles over 150 extractions per day

- Automatic Solvent Recycling system recovers ~97% of solvent, minimizing waste and operating costs

- Integrated Activated Charcoal Filter eliminates the need for a vent hood

- Solvent usage per sample is approximately 0.5 mL, supporting sustainable lab practices

- High-temperature operation at 90°C accelerates extraction kinetics, reducing most extractions to under 40 minutes

- Filter bag system simplifies sample handling and enables efficient batch processing

- Compatible with solvents like Petroleum Ether and Hexane without seal replacement; ask about upgrades for diethyl ether

Benefits

- Efficient and economical – Official AOCS method ensures reliable results with minimal labor

- High throughput – Extracts large sample volumes daily, perfect for production or QA/QC labs

- Safe and cost-saving – No vent hood required, reducing infrastructure and maintenance costs

- Eco-friendly – Solvent recycling system significantly reduces environmental impact and consumables

- User-friendly – Automated operation reduces manual error and operator intervention

Why Choose the Ankom XT15?

The Ankom XT15 Extractor is a smart solution for labs seeking accurate, fast, and automated solvent extraction. From food and feed to environmental testing, it delivers consistent results with less downtime, minimal solvent usage, and no need for fume hoods. An ideal fit for high-volume operations that demand reliability and compliance.