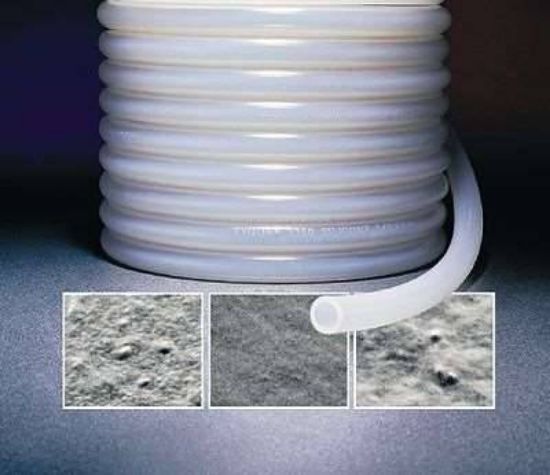

VWR Tygon Silicone Tubing provides flexible, durable, and chemically resistant tubing for pharmaceutical, cosmetic, industrial, and auto-analysis applications. Its ultra-smooth inner surface reduces particle entrapment and minimizes bacterial growth, ensuring safe and reliable fluid transfer. This tubing is FDA-compliant, meets USP Class VI, NSF, and EP 3.2.9 standards, and is manufactured according to GMP guidelines. Temperature range is –112 to 392°F (–80 to 200°C), and it can be sterilized using ethylene oxide, gamma irradiation, or autoclaving for 30 min at 15 psi.

Product Features

- Formulation: TYGON 3350 silicone, platinum cured

- Characteristics: Ultra-smooth inner surface reduces particle entrapment and minimizes bacterial growth; good for mild to medium concentration bases, salts, and alcohols; odorless, tasteless, non-toxic; transparent

- Certification: FDA-compliant (21 CFR 177.2600), meets USP Class VI, NSF, and EP 3.2.9 requirements; manufactured according to GMP

- Temperature Range: –112 to 392°F (–80 to 200°C)

- Sterilization: Can be sterilized with ethylene oxide, gamma irradiation, or autoclave (30 min, 15 psi)

Applications

- Pharmaceutical processes

- Cosmetic manufacturing

- Industrial fluid handling

- Auto-analysis applications

Benefits

- Ensures reliable and safe fluid transfer in sensitive applications

- Durable and flexible tubing suitable for a wide range of chemicals and temperatures

- FDA and USP Class VI compliance guarantees compatibility with pharmaceutical and food applications

- Transparent tubing allows visual inspection of fluid flow

Why Choose VWR Tygon Silicone Tubing?

VWR Tygon Silicone Tubing offers high chemical resistance, flexibility, and compliance with international standards, making it ideal for laboratory, industrial, and pharmaceutical uses where safety and reliability are critical.