The GUNT Tubular Heat Exchanger WL 110.01 provides a simple and effective solution for studying heat transfer between fluids with high pressure differences or high viscosity media. It allows experiments in parallel flow and counterflow, providing clear visualization of temperature changes and heat transfer characteristics.

Product Features

- Hot water flows through the inner tube and cold water through the outer tube, transferring thermal energy from hot to cold water.

- Valves on the supply unit adjust flow rates; quick-release couplings allow flow direction to be reversed for parallel flow or counterflow operation.

- Temperature curves are plotted and displayed graphically; mean heat transfer coefficient is calculated as a characteristic variable.

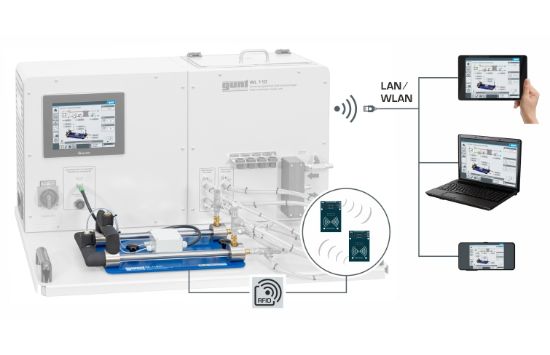

- Accessory easily and safely positioned on WL 110 supply unit; RFID technology automatically identifies the accessory, loads appropriate PLC software, and performs system configuration.

- Intuitive user interface guides through experiments; up to 10 external workstations can track and evaluate experiments simultaneously via LAN.

- Temperature sensors located at inlet and outlet connections; two additional sensors measure temperature at half the transfer distance.

- Supply of hot and cold water, flow setting, and temperature measurement controlled via the supply unit.

Benefits

- Provides clear, practical study of heat transfer in tubular heat exchangers.

- Flexible flow configuration for parallel and counterflow experiments.

- Intuitive software interface and RFID technology ensure quick setup and automatic system configuration.

- Supports multiple workstations for simultaneous tracking and evaluation of experiments.

Why Choose GUNT Tubular Heat Exchanger WL 110.01?

The GUNT WL 110.01 Tubular Heat Exchanger provides a safe, flexible, and intuitive platform to study heat transfer, flow configurations, and temperature measurement, ideal for teaching and laboratory research.