Configurable to your needs - active solvent and waste level sensing, along with column air purge, is standard. The system is designed for liquid injections, operating at up to 300 psi (20 bar). Similarly, RFID rack and column read can be added if desired. You determine what your needs are; don’t invest in unused or unwanted features.

The Focus Gradient Generator feature, which provides predictive method development, is included with ISCO’s PeakTrak software for the CombiFlash NextGen. This feature enables a user to select the target peak for purification from the results of a preset gradient run. It then quickly generates an optimized gradient method focused around that peak

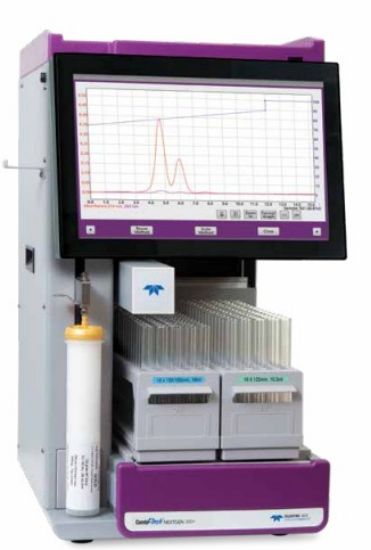

Save Time, Save Space

- Flow rates from 1 to 300 mL/min

- Operating pressure up to 150 psi (10 bar) Can be upgraded to 300 psi (20 bar)

- Wider Dynamic Range UV Detector

- Improved baseline correction supports use of absorbing solvents

- Faster processing with streamlined user interface

Photo Diode Array Detection

- UV and UV-Vis detectors use PDA technology

- Display spectra in real time or post-run

- Collect based on purity indicators

Internal Vapor Sensor

- Automatically stop the system if vapors are detected (level is user-configurable) for safe operation

Mass Directed Purification

- Collect only those peaks matching the mass of your compound

- Eliminate the need for further analysis—save time in post-purification processing

Integrated ELSD to Collect Non-Chromophoric Non-Volatile Compounds

- Integrated into the CombiFlash: No additional system footprint

- All parameters programmed based on the solvent used or optimize operating conditions for your separation

- Offers scalability and sensitivity for a wide sample load range