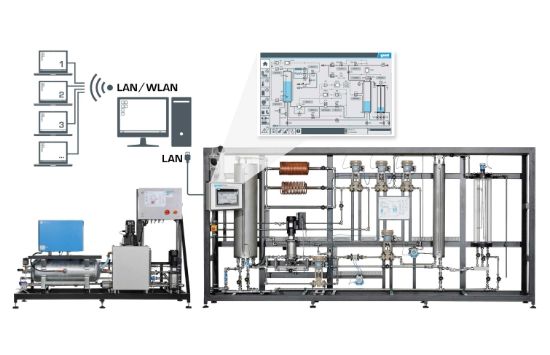

The GUNT Process Control Engineering Experimental Plant simulates centralized supply and control of industrial processes with water and compressed air. It includes a separate supply unit and a trainer with a touchscreen for precise process control and monitoring.

Product Features

- Integrated water circuit with pump, collecting tank, and graduated tank for flow rate and level control

- Electropneumatic control valves as actuators for accurate regulation

- Speed-controlled pump with frequency converter for flexible flow control

- Level control options including under counter pressure and cascade control

- Transparent tank option to facilitate learning of second-order level control systems

- Pressure control using compressed air with graduated tank as the controlled system

- Temperature control in collecting tank or inlet by mixing cold and warm water via control valve

- Three delay sections to simulate different dead times in the system

- Practical fault analysis with simulated faults like cable breaks and frozen measurements

- Operated via integrated PLC with touchscreen or PC software for process control and data acquisition

- Multiple workstations connect via LAN/WLAN with a single software license for observation and evaluation

Benefits

- Realistic training environment for centralized industrial process control

- Hands-on learning with advanced control strategies and fault diagnostics

- Flexible system configuration supports various control scenarios

- Data acquisition and parameterisation improve experimental analysis

- Networking capabilities allow collaborative training and remote monitoring

Why Choose the GUNT Process Control Engineering Experimental Plant?

This experimental plant offers a comprehensive, practical platform to study and train in industrial process control using water and compressed air media. Its integrated software, versatile control options, and fault simulation make it invaluable for engineering education and research.