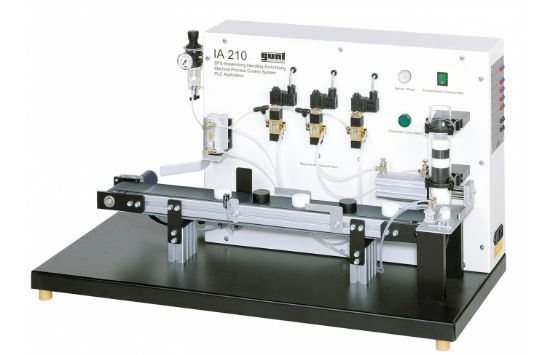

The GUNT PLC Application Unit for Materials Handling Process is a compact teaching and practice unit designed to control materials handling using a PLC. It simulates two processes: a punching process and a workpiece sorting operation. All components are clearly laid out for easy operation and understanding.

Product Features

- Simulates handling of black and white cylindrical workpieces fed from a container onto a conveyor belt

- Reflex photoelectric proximity switch on the conveyor differentiates between light and dark workpieces

- White workpieces are directed to either punching or sorting processes based on pre-selection

- Black workpieces are carried to the end of the belt and collected separately

- Three 5/2-way solenoid valves, three double-acting cylinders, and a pneumatic roller pushbutton are controlled via PLC

- Enables workpiece release, conveyor feeding, sorting, and punching operations

- Punching mode positions workpiece precisely with the ability to switch between sorting and punching sequences

- Designed for operation with a PLC module; use with GUNT PLC module IA 130 is recommended

Benefits

- Provides practical experience in PLC-controlled materials handling processes

- Clear layout aids understanding of pneumatic and automation components

- Supports learning of sequence control and sensor integration in industrial automation

- Ideal for hands-on training in punching, sorting, and conveyor control operations

Why Choose the GUNT PLC Application Unit for Materials Handling?

This unit offers realistic simulation of industrial materials handling controlled by PLCs, combining pneumatic components and sensors. It is an excellent training tool for automation technology education and practical PLC programming.