The GUNT WL 110.05 Finned Tube Heat Exchanger provides a practical platform for studying enhanced heat transfer using fins to increase the surface area. This unit demonstrates cross-flow heat exchange between hot water and ambient air, simulating applications such as air coolers for combustion engines.

Product Features

- Box-shaped profile allows air to flow across pipe sections carrying hot water, creating cross-flow heat transfer.

- Fins attached to the pipe sections increase the heat-transferring surface for more efficient energy exchange.

- Hot water transfers part of its thermal energy to the air, demonstrating practical finned-tube heat exchanger operation.

- Temperature curves are plotted and displayed graphically during experiments.

- Positioned easily and securely on the WL 110 supply unit work surface.

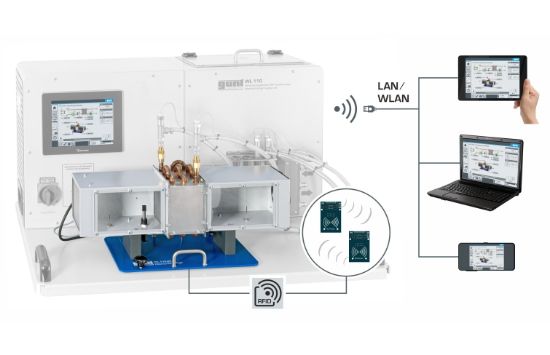

- RFID technology automatically identifies the accessory, loads GUNT software, and configures the system automatically.

- Intuitive user interface guides experiments and displays measured values graphically.

- Up to 10 external workstations can monitor and analyze experiments simultaneously via LAN connection.

- Temperature sensors measure inlet and outlet water temperatures; two additional sensors measure air temperature.

- Flow velocity of air is recorded; hot water supply, flow rate settings, and temperature measurements are controlled via WL 110 supply unit.

Benefits

- Demonstrates efficient heat transfer enhancement using fins.

- Clear observation of cross-flow heat exchange between water and air.

- Integrated RFID and software simplify experiment setup and data collection.

- Supports simultaneous monitoring on multiple workstations for educational and research purposes.

Why Choose GUNT Heat Exchanger WL 110.05, Finned Tube?

The GUNT WL 110.05 Finned Tube Heat Exchanger offers a reliable and safe platform for studying enhanced heat transfer using fins, suitable for education, research, and process engineering applications.