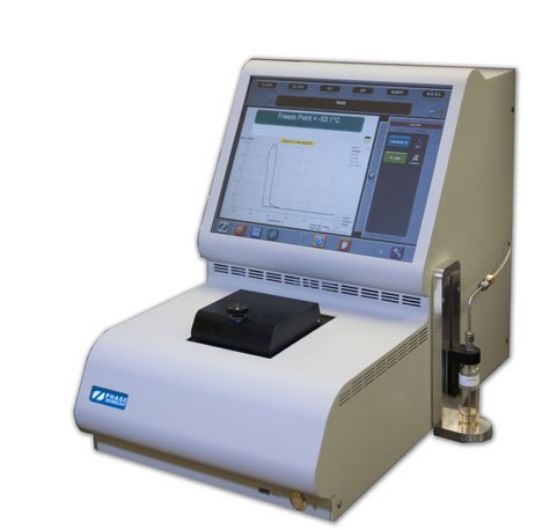

The Phase Freeze Point Analyzer with Single Shot Automatic Sample Injection offers quick, precise freeze point testing with minimal user effort. Featuring a side-loaded automatic sample injection port, this analyzer eliminates manual pipetting and automatically draws the exact sample volume required by ASTM methods. Fully self-cleaning without solvents, it streamlines lab workflows while maintaining exceptional accuracy and reliability.

Product Features

- Best overall precision of any automatic or manual method

- Fastest speed of any cloud, pour or freeze point analyzer: test results in just 8-20 minutes

- Easy-to-use and versatile: saves time in the lab, no special training needed

- Automatic sample input – No pipette required. New vial injection system loads sample automatically

- Self cleaning – no solvent required

- One-touch preset Favorites – Store frequently used test settings for quick access

- Full-color, touch-sensitive, 15” high resolution screen with multitasking capability

- USB and Ethernet connectivity for fast data export, remote diagnostics, and device integration

- Robust modular design with field-replaceable parts for easier, faster service without re-calibration

- Powerful cooling system; minimum sample temperature below -88°C (-126°F)

- User programmable resolution to 0.1°C

- Unsurpassed detection of contamination in jet fuels

- Programmable user access levels to streamline workflow and prevent accidental changes

- Alert sounds indicate test completion and readiness for next run

- Compatible with HP or PCL printers via USB

- Import and store SOPs and training documents in multiple formats

- Sample chamber positioned lower and more upfront for easier loading, cleaning, and less spill risk

- Chamber lid LED indicator shows test status

- New front panel power button and software-enabled shutdown

- Configurable desiccant replacement count

- Customizable reporting: test history, plot data, and diagnostics can be displayed, printed, or transferred for analysis

- Small sample volume required

- Completely self-contained system with no need for external coolant

- Quiet, energy efficient, and environmentally friendly with no toxic coolant vapors

Benefits

- Significantly increases lab productivity and profitability with fast, precise results

- Eliminates manual pipetting errors with automatic sample injection

- Reduces downtime through self-cleaning operation without solvents

- Intuitive interface and customizable presets save time and simplify workflows

- Reliable, modular design enables fast maintenance without calibration delays

- Advanced connectivity and reporting streamline data management and compliance

- Compact and quiet design fits seamlessly into busy laboratories

Why Choose The Phase Freeze Point Analyzer With Single Shot Automatic Sample Injection?

Engineered for speed, precision, and ease of use, the Phase Freeze Point Analyzer with Single Shot Automatic Sample Injection is the ideal choice for labs requiring fast turnaround and dependable results. Its automatic injection and self-cleaning features reduce operator workload while enhancing accuracy and reliability. Perfect for petroleum, chemical, and quality control applications, this analyzer helps laboratories optimize efficiency and maintain the highest standards.