Design according to the specifications given as specified by the end user

- continuously working distillation unit

- feed: approx. 500 t/a, approx. 40-50 wt% of Hydrogen Peroxide in water

- product: at least 90 wt% of Hydrogen Peroxide

- waste: less than 5% of Hydrogen Peroxide in water

- operation temperature: 40-60°C

- vacuum equipment for 25 mbar and less

- explosion-proof equipment

FFKM, FEP

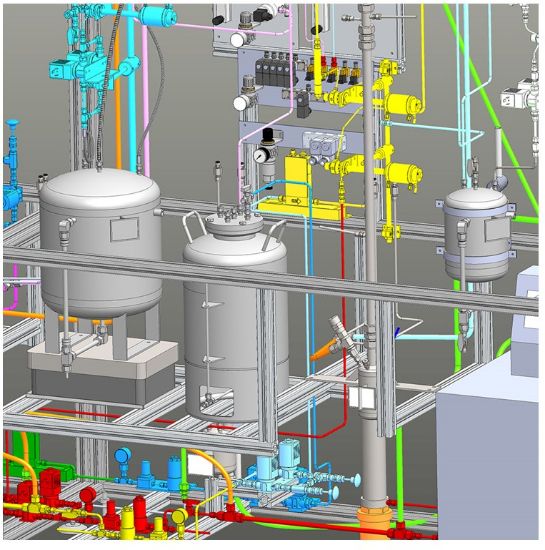

Mains Supply: 240/415 V, 3 P + N + PE, 50 Hz, max. 250 kW Dimensions (L x D x H): approx. 3.5 x 2.5 x 8.5 m³, tbc Installation Conditions: indoor, others on demandThe system consists of:

- reboiler, consisting of bundle tube heat exchanger, forced circulation pump, separation chamber

- separation column, packed with structured packing, complete with necessary supports and liquid distributors

- column head consisting of condenser and reflux divider

- cooler for the concentrated hydrogen peroxide

- pump to discharge the product from vacuum to atmospheric conditions

- cooler for the waste water stream

- intermediate receiver and pump to discharge the waste water from vacuum to atmospheric conditions

- vacuum system consisting of vacuum pump and cooling trap with cryostatic circulator

- hot water unit to serve the evaporator

- cold water unit to serve condenser and coolers

- all required control equipment, this is in particular:

- control valve and mass flow meter for feeding

- all necessary temperature and pressure probes and level sensors

- control unit for automatic and unattended operation, with storage

- all required piping, hoses, valves, electrical cabling and cable trays

- all required safety equipment and thermal insulation

- mounting frame with internal levels for servicing, with staircase and guard rails, but without housing

All equipment according to European regulations. Hot water unit, cold water unit and controller are due to cost reasons are NOT ex-proof and must be installed in a safe area.

Scope of supply does not include equipment such as:

- storage vessels for raw material, product or waste

- piping and cables outside the installation frame of the unit, except connection of hot water unit and cold water unit

- grounding works and works at the installation building