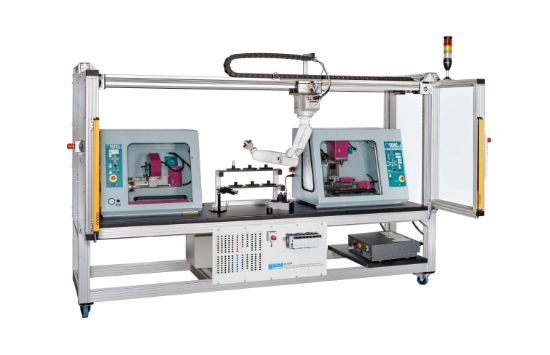

The GUNT Computer Integrated Manufacturing and Handling System represents a fully functional CIM cell (Computer Integrated Manufacturing). The system allows an automated manufacturing process to be created. It demonstrates the basic processes of handling (robots), manufacturing (CNC machining), and control (PLC).

Product Features

- An overhead robot on a travel unit supplies two CNC machines with raw parts taken from a magazine

- The machined dimensions of parts are checked in an inspection station before placement in a finished parts store

- Defined planning and control data is used to control various machines, stored in software and processed by individual machine control units

- A PLC system monitors and controls the entire process

- The manufacturing cell is equipped with all necessary sensors and control devices

- Control and programming software for CNC machines, robot, travel unit, and PLC (monitoring and control) are installed on two PCs

- Sequences in the CIM cell can be altered by modifying the PLC programming

- Patchboard allows flexible interconnection of control inputs and outputs, enabling flexible configuration and custom concepts such as integration of additional elements

- A demo program for a manufacturing process is included

- Safety devices prevent access to the working area during operation of the CIM cell

Benefits

- Provides hands-on experience with automated manufacturing and integrated control

- Combines robotics, CNC machining, and PLC control in one system

- Flexible programming and configuration to simulate real-world manufacturing processes

- Equipped with safety features for secure training environment

- Ideal for advanced training in manufacturing automation and control engineering

Why Choose the GUNT Computer Integrated Manufacturing and Handling System?

This system offers a comprehensive, realistic CIM cell for education and training in modern automated manufacturing and control engineering.