The Cole-Parmer Production Weighing System 320g delivers high-precision weighing with adjustable stabilization speeds, designed to optimize production line performance. Its compact footprint, versatile mounting options, and GLP/GMP-compliant output make it ideal for demanding industrial and laboratory environments.

Product Features

- High-precision weighing and adjustable speed to stabilization optimize production line weighing

- FAST, MID, and SLOW stabilization settings let you choose the right combination of response time and sensitivity for your application

- Compact footprint and mounting fixtures make integration into existing production line systems easy

- Create your own weighing pan to better suit your samples

- Separate sensor and display units are perfect for isolated weighing inside vacuum chambers, fume hoods, and glove boxes

- Display unit can be panel- or wall-mounted

- Patented shock absorber fitted under the weighing pan protects sensor from vertical and transverse overloads

- Standard bidirectional RS-232 interface connects to PC for data download and control

- Output conforms to GLP/GMP requirements

Benefits

- Extremely quick Super Hybrid Sensor technology offers response times as low as 0.5 seconds for fast-paced weighing and filling operations

- Flexible placement of the compact weighing sensor anywhere in your production line

- Custom-designed weighing pans for diverse sample needs

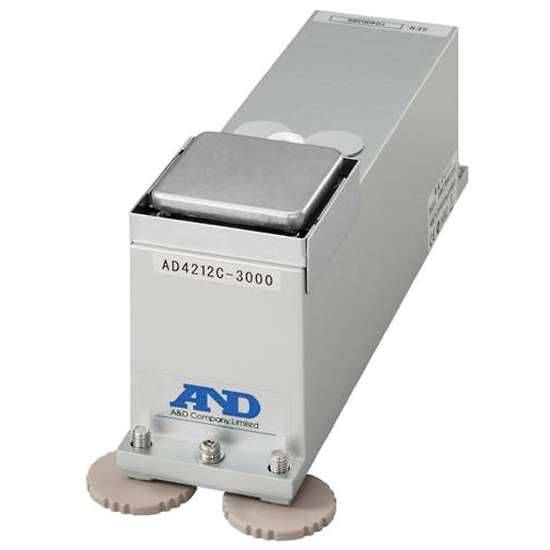

- Robust IP65-rated AD-4212C sensor withstands dust, powder spills, and washdown conditions

- Large data memory supports storage of weight measurements, calibration, and comparator settings

- Ensures compliance with GLP/GMP data output standards for quality assurance

Why Choose the Cole-Parmer Production Weighing System 320g?

Combining speed, precision, and ruggedness, the 320g model is perfect for high-demand production lines and environments requiring washdown capabilities. Its advanced sensor technology and flexible mounting options ensure reliable operation and seamless integration.