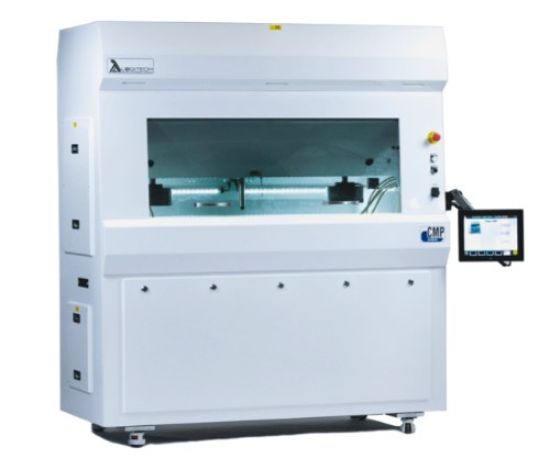

The Logitech CMP Orbis Chemical Mechanical Polishing System is a state-of-the-art platform designed for precise wafer polishing applications. Featuring a PC-driven control system with a touchscreen interface, this system ensures exact process control and repeatability. Equipped with a twin-feed slurry delivery system and an advanced wafer carrier head, it supports wafer diameters from 8 mm up to 200 mm, making it suitable for a wide range of semiconductor manufacturing and research tasks.

Product Features

- PC-driven control system with intuitive touchscreen interface for easy operation

- Twin-feed slurry delivery system for precise and consistent polishing

- Wafer carrier head capable of handling wafers from 8 mm to 200 mm diameter

- Integrated pad conditioning system to maintain polishing pad quality and extend lifespan

- Automated process control for improved reproducibility and efficiency

- Designed for chemical mechanical polishing in semiconductor and materials research

Benefits

- Accurate and repeatable polishing processes enabled by advanced PC control

- Enhanced polishing uniformity with precise slurry delivery and pad conditioning

- Flexible wafer size capacity accommodates a broad range of applications

- Improves throughput and reduces downtime through automation

- User-friendly interface simplifies process setup and monitoring

Why Choose the Logitech CMP Orbis?

The Logitech CMP Orbis Chemical Mechanical Polishing System offers precision, flexibility, and advanced control for semiconductor manufacturing and research labs. Its comprehensive features including twin slurry delivery and pad conditioning ensure consistent, high-quality polishing results. This system is an excellent choice for facilities seeking reliable, scalable, and easy-to-use CMP solutions.